The term “Blue Hydrogen” refers to hydrogen generation processes that minimize CO2 emissions. The CO2 emissions are reduced via absorption from the hydrogen rich process gas (pre-combustion CO2 Capture) or the reformer flue gas (post-combustion CO2 Capture). The absorption is typically accomplished with an amine based solvent, but physical solvents are a viable alternative. Lummus offers a range of blue hydrogen solutions, including both pre-combustion and post-combustion CO2 capture, to fit the needs of each customer. The table below summarizes the CO2 removal level of the options offered by Lummus.

| CO₂ Capture Option | Description | % CO₂ Removal |

|---|---|---|

| SMR with Pre-Combustion CO₂ Capture | CO₂ is removed from the cooled synthesis gas before any additional purification. | 50-70% |

| SMR with Post-Combustion CO₂ Capture | CO₂ is removed from the reformer flue gas. | 90%+ |

| SMR with Pre and Post-Combustion CO₂ Capture | CO₂ is removed from the synthesis gas and from the flue gas. | 95%+ |

| ATR with CO₂ Capture | Oxygen is used as fuel instead of fuel gas and the reforming and oxidation reactions are carried out in a single step. CO₂ is removed from the cooled synthesis gas before any additional purification. | 93-98% |

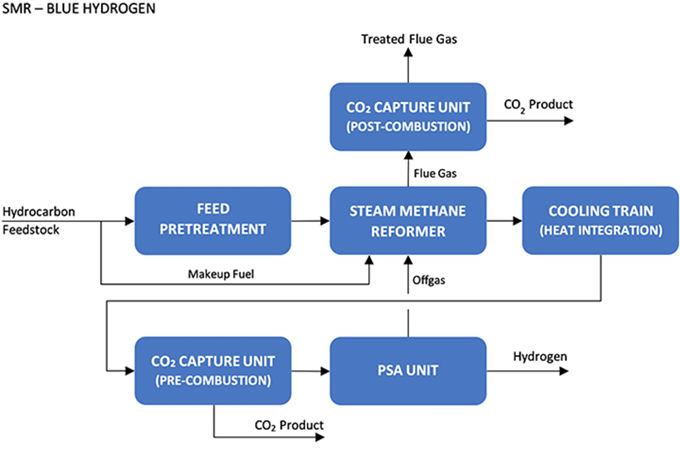

Blue Hydrogen - SMR

Lummus’ hydrogen plants based on SMR technology can be modified to accommodate either pre‑combustion or post-combustion CO2 capture. The feed is first treated to remove catalyst poisons such as sulfur and chloride in the pretreatment section. The feed is then mixed with steam and sent to the SMR where hydrocarbons are reformed to hydrogen and carbon oxides. Heavier feedstocks will have a prereforming step, where the heavier components are partially reformed. The effluent from the SMR then passes through a water-gas shift reactor where residual CO is converted into additional hydrogen via the water-gas shift reaction. After the shift conversion step, the hydrogen rich gas stream is cooled and then, for plants with pre-combustion CO2 capture, passes through an amine absorber in which CO2 can be removed to levels below 100 ppmv. After CO2 removal, the hydrogen rich gas can be purified to 99.9%+ in a Pressure Swing Adsorption (PSA) unit if required. For plants with post-combustion CO2 capture, the cooled flue gas from the reformer is passed through an amine absorber where 90%+ of the CO2 is removed before the flue gas is vented to atmosphere. For both pre and post-combustion CO2 capture, the amine is regenerated in an Amine Regeneration Unit (ARU) and the CO2 product is compressed and exported. Lummus also offers a patented CO2 liquefaction process if liquid CO2 product is required.

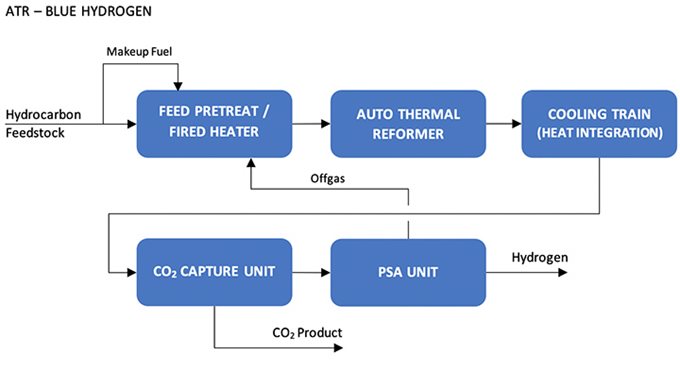

Blue Hydrogen - ATR

In addition to SMR based blue hydrogen, Lummus has also adapted its ATR technology to provide a reliable method of capturing high percentages of CO2 via pre-combustion CO2 capture. The feed is first treated to remove catalyst poisons such as sulfur and chloride in the pretreatment section. The feed is then mixed with steam, preheated in a feed fired heater or heat exchanger and sent to the ATR where hydrocarbons are reformed to hydrogen and carbon oxides. Heavier feedstocks will have a prereforming step, where the heavier components are partially reformed. The effluent from the ATR then passes through a water-gas shift reactor where residual CO is converted into additional hydrogen via the water-gas shift reaction. After the shift conversion step, the hydrogen rich gas stream is cooled and then sent to an amine absorber in which CO2 can be removed to levels below 100 ppmv. After CO2 removal, the hydrogen rich gas can be purified to 99.9%+ in the PSA unit if required. The amine is regenerated in an Amine Regeneration Unit (ARU) and the CO2 product is compressed and exported. Lummus also offers a patented CO2 liquefaction process if liquid CO2 product is required.

Revamps

As the global energy transition progresses, hydrogen plant owners will be compelled to either replace or retrofit their existing units with CO2 capture in order to produce blue hydrogen. Lummus’ extensive experience ensures it is well-suited to handle these revamp opportunities. Whether a customer is looking for a cost-benefit study or the design and supply of equipment, Lummus can provide an efficient and cost‑effective solution.