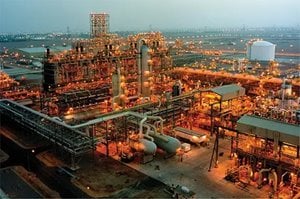

Lummus Technology is a leading supplier of hydrogen and synthesis gas plants for refinery, petrochemical and other industrial gas applications. Lummus designs hydrogen and synthesis gas plants utilizing: steam methane reforming (SMR), steam/oxygen reforming (SMR/O2R) and auto-thermal reforming (ATR) technology with natural gas, LPG and/or naphtha feedstocks. Over the past 50 years, Lummus has designed and supplied more than 200 plants worldwide.

Lummus’ hydrogen technology provides solutions for both conventional hydrogen and blue hydrogen production. Conventional hydrogen production emits CO2, produced from reactions and combustion, to the atmosphere. Blue hydrogen production captures the CO2 and stores or utilizes it in a down-stream process. This hydrogen technology is part of Lummus’ Green Circle LLC entity, which is focused on the circular economy and energy transition.

Download Technology Sheet

Download Technology Sheet

Hydrogen

Lummus’ hydrogen technology provides solutions for both conventional hydrogen and blue hydrogen production. Conventional hydrogen production emits CO2, produced from reactions and combustion, to the atmosphere. Blue hydrogen production captures the CO2 and stores or utilizes it in a down-stream process. This hydrogen technology is part of Lummus’ Green Circle LLC entity, which is focused on the circular economy and energy transition.

Hydrogen