Known for its wide range of applications, polypropylene is a high demand product that traditionally requires high amounts of energy to produce. Through years of research and development, Lummus has refined its polypropylene technology to reduce energy consumption dramatically, improving project economics for customers around the world.

- Novolen ComPPact® process reactors

- Single reactor, cascade reactors, parallel reactors, or the versatile cascade/parallel VRC® reactor configuration, allowing for maximum product range and capacity flexibility.

- NEON® extrusion equipment design for low VOC products

- Specialized Lummus Digital solutions for process & operation optimization

- Life Cycle Services that will be customized to the requirements of the licensee

- Our catalyst collection includes NHP® catalysts and Novocene® metallocene catalysts which produce high-performance and special polypropylene grades Novolen CirPPlus™ (recycled polymers), Novolen Enhance™ (performance-boosting polymers enabling mechanical recycling), and non-phthalate PPure™.

Tailor-made reactions improving project economics

Lummus’ bespoke Novolen High Performance (NHP) catalysts, custom made to optimize polypropylene production, open the world of high-performance and special grade polymer production to Novolen technology licensees. Catalysts improve project economics by steering reactions to higher conversions and yields. Whether you desire to support the environment through recycled polymers or achieve next-generation performance through metallocenes, NHP catalysts help producers differentiate their products with consistent, high-quality performance.

Additional information:

Our catalyst collection includes NHP® catalysts and Novocene® metallocene catalysts which produce high-performance and special polypropylene grades Novolen CirPPlus™ (recycled polymers), Novolen Enhance™ (performance polymers), and PPure™.

Polyethylene is the world's most widely produced plastic, forming the foundations for applications from rigid, durable goods to soft, flexible films, and various other products such as pipes, storage containers and drums. Our portfolio of leading polyethylene technologies provide safe, reliable and cost-effective solutions that enable producers to manufacture the full spectrum of polyethylene products across a wide range of applications.

- Research facilities like bench scale and pilot plant reactors are used for catalyst, process, and product development work which are based on sound Engineering and technical know how.

- Two agitated slurry phase polymerization reactors equipped with a polymerization heat removal system

- Proven technology with multiple operating plants catering to a wide market base

- Single catalyst - EL-CAT™ which is a Ziegler catalyst yielding high productivity. Use of single catalyst avoids any downtime or production loss associated with the catalyst type transitions.

- Both tubular and autoclave process technologies

- High-pressure double-autoclave reactors

- Wide variety of LDPE products with good melt strength

- Superior products with high EVA content (up to 40%) for specialized and high growth applications

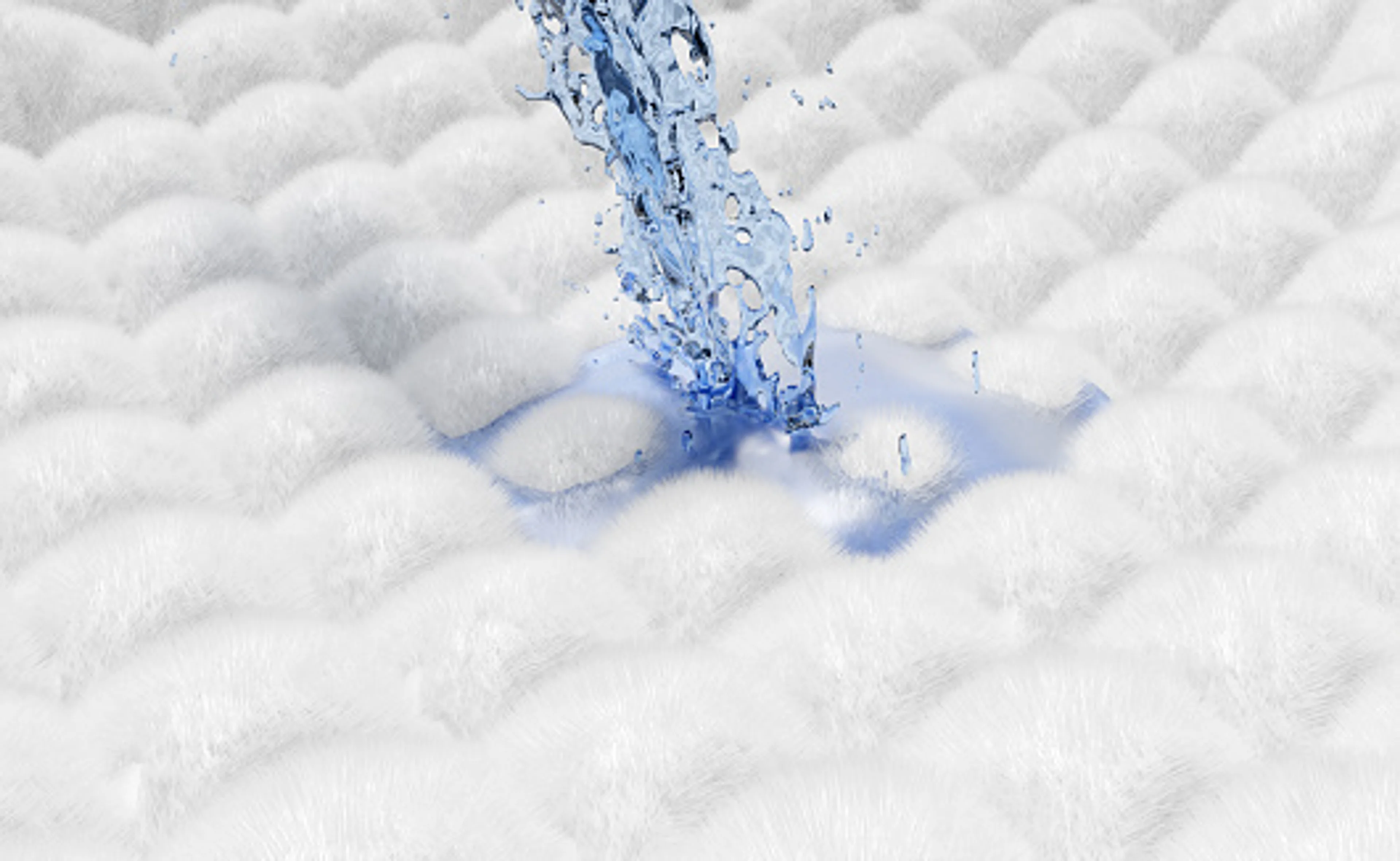

Designed to capture and retain large volumes of liquid, super absorbents power critical hygiene and agricultural products around the world. Lummus is proud to be the only global licensor with a fully integrated production process covering the entire manufacturing chain (including C3, AA, and GAA production).

- Saplene operates without the need for organic solvents, making the process intrinsically safer and more economical by avoiding the complexity and cost of solvent recovery systems. This also contributes to a reduced environmental footprint.

- At the heart of the process is the belt reactor—the most popular commercial technology for SAP production—recognized for its flexibility in tuning product properties, adaptability to new generations of hygiene articles, and its ability to deliver a well-balanced performance profile across absorbency, retention under pressure, and permeability.

As the world transitions to a circular economy, managing plastic waste has become a critical priority. Our advanced circular technologies are at the forefront of this transformation, providing comprehensive solutions for producers to achieve their sustainability goals and creating a cleaner, more sustainable future for all.